The Hidden Costs That Make “Cheap” Sourcing Expensive

In almost every conversation with procurement managers and business owners, I hear the same sentence:

“We need the best price.”

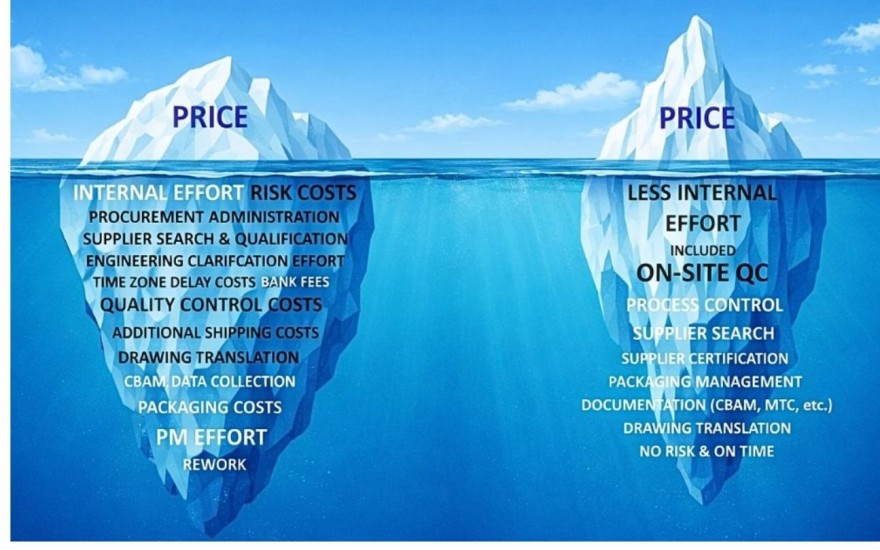

I completely understand. Unit price is easy to compare, easy to measure—and it looks like the most important KPI. But that’s exactly where the risk begins: price is only the tip of the iceberg. Below the waterline sits a long list of costs that are often ignored in early evaluations - and paid later.

The iceberg below the waterline: hidden procurement costs

When companies buy directly in Asia, they often see only PRICE. What they don’t see upfront are the internal and external add-on costs that accumulate, such as:

-

RISK COSTS (quality issues, delays, rework, claims)

-

ADDITIONAL SHIPPING COSTS (surcharges, expediting, detours)

-

EXTRA PACKAGING COSTS (damage prevention, repacking, labeling)

-

INTERNAL EFFORT (clarifications, follow-ups, time-zone friction)

-

DOCUMENTATION & COMPLIANCE COSTS (MTC, reports, import docs, CBAM data)

-

ADDED QC COSTS (third-party inspections, re-checks, sorting)

-

PROJECT MANAGEMENT COSTS (tracking, escalations, changes)

-

PROCESS OVERSIGHT (continuous monitoring and corrective actions)

These costs rarely show up in the first quote comparison—but they are very real. And they consume time, resources, and focus.

Why SolidTechnics can look more expensive at first glance

At SolidTechnics, customers sometimes tell us:

“You are more expensive than others.”

That may be true - if you only compare unit price.

But we are not a classic trader, not a simple sourcing middleman, and not a quote-forwarding agency.

We deliver an ALL-IN Sourcing model designed to reduce or remove hidden costs by providing:

-

active procurement relief for Western teams

-

professional specification and communication bridging in Asia

-

on-site QC as a risk shield before shipment

-

continuous project and deadline monitoring with immediate intervention

-

packaging and handling guidelines

-

documentation and compliance reliability

Honestly calculated: you end up paying less

When you calculate TOTAL COST OF OWNERSHIP and the TRUE TOTAL PROCUREMENT COSTS, the picture becomes clear:

A “cheap” supplier can become the most expensive decision.

Our ALL-IN approach creates a stable, predictable supply chain - and gives Western companies the ability to focus on what truly matters: innovation, sales, customers, and growth.

Why I keep explaining this to customers

I’m Sascha Opperer, CEO of SolidTechnics - and yes, I explain this iceberg over and over again.

Not because it’s a nice sales phrase, but because I’ve seen it repeatedly in real projects.

Our long-term loyal customers stay for exactly this reason:

They learned that a reliable partner in Asia is worth more than a seemingly cheap price.

We’re proud not to follow the crowd.

And I truly believe: this is the better way - for both sides. Win-win.

If you want, let’s look at your parts together - and run an honest calculation: Price vs. Total Cost.

—

Sascha Opperer

CEO | SolidTechnics